- Solutions

Our Services

R+D+i Consulting

Integrated consultancy service for projects of strategic interest with high market potential

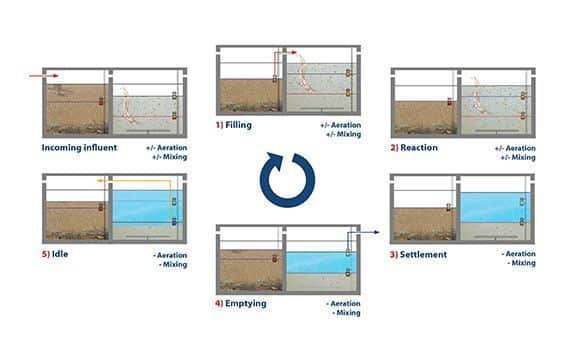

Water Engineering

Tailored industrial and urban wastewater treatment solutions

Technologies and Products

Wastewater treatment, humidification and energy efficiency systems

- Projects

- Updates

- About us